The Single Strategy To Use For Steel Road Plates

The Single Strategy To Use For Steel Road Plates

Blog Article

How Steel Road Plates can Save You Time, Stress, and Money.

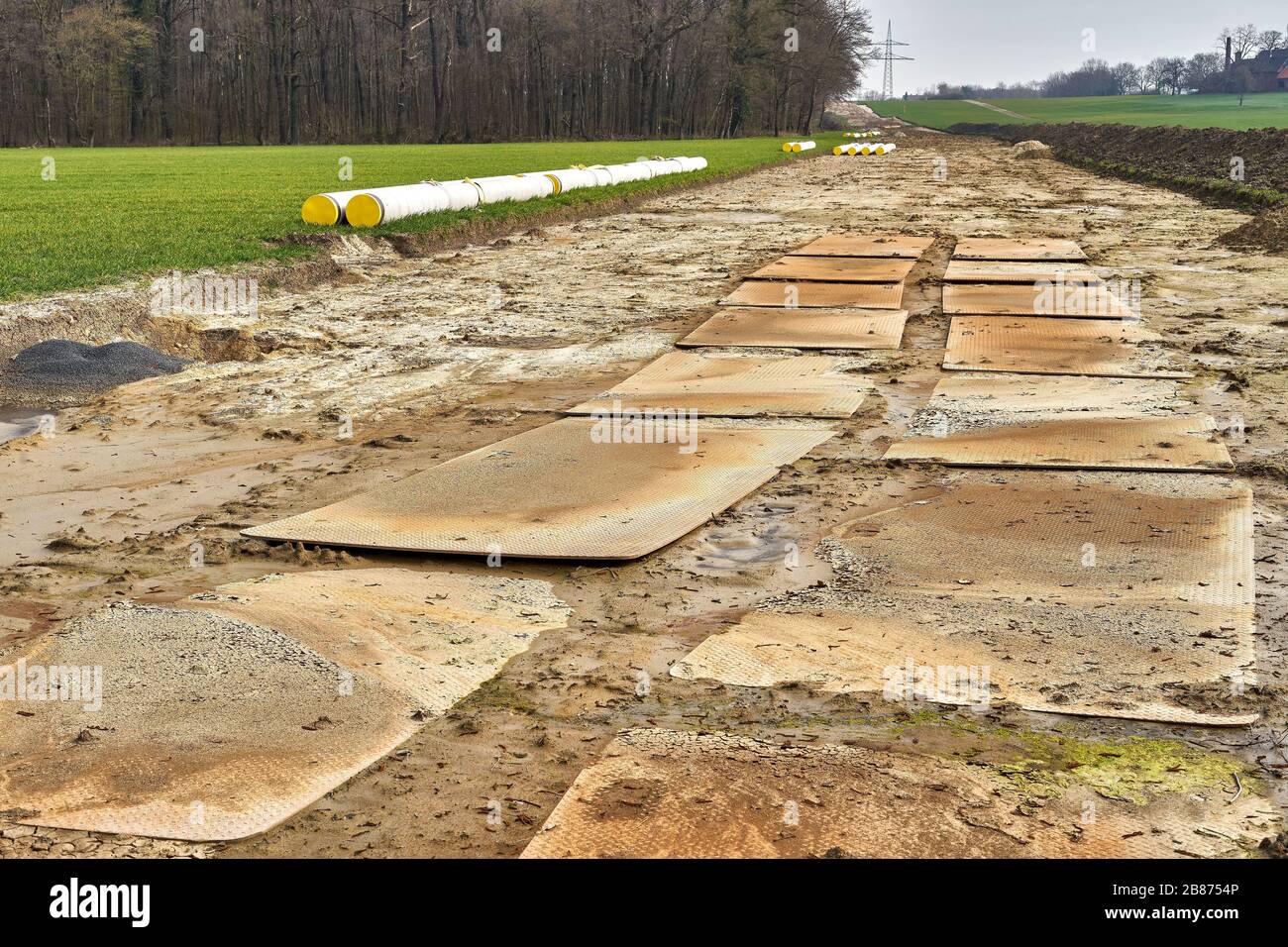

These heavy-duty, durable plates allow roads to return to service so that building can proceed. These plates can be used to guarantee that roads can still be made use of whilst other stages of job proceed.

They are typically seen when excavations have actually started as a very early phase of construction or repair projects. These plates are made to endure sturdy use on hectic roadways.

The weights start from roughly 300kg and conventional road plates have a thickness of either inch or inch. The capacity to be bolted to the roadway.

How Steel Road Plates can Save You Time, Stress, and Money.

Hinged variations for quick accessibility to the excavation or regular gain access to, e.g. driveways. Compound plates, which can fit various lengths of trench. Skid-resistance for improved automobile, pedestrian and website employee safety and security. Steel roadway layers can be mounted rather quickly, but they are heavy. Consequently, they should be installed making use of a forklift or crane.

Look for variation by web traffic loading from the outset plates need to always resist displacement. Inspect that the plates do not present a hazard to any kind of kind of roadway user and can be used by all roadway individuals and lorry types, consisting of pedestrians, cyclists and motorcyclists. Develop a normal assessment and maintenance to ensure that performance continues to be safe and optimal.

Take care of the plates appropriately at all times. Mechanical training ensures that the plates are installed accurately and safely.

If a ramp is produced by the roadway plates, then cautioning signs for pedestrian and road customers are called for. Constantly a conduct complete site survey, and take the professional advice of an architectural designer. The Division of Transport also offers guidance on installing roadway plates, please click below. SafeSite Facilities (Steel road plates)' roadway plates are readily available for buy or employ anywhere in the UK.

The Buzz on Steel Road Plates

In order informative post to boost safety and security, there are a variety of standards and industry files guiding their usage in building and construction work areas. This article offers some highlights that might be useful in beginning your examination. If you require extra details, please contact our expert directly. Steel plates have to be fixed in location to stay clear of movement.

5 Easy Facts About Steel Road Plates Shown

In addition to being strongly touching the pavement, they should be either pinned, recessed into the sidewalk, or safeguarded with asphalt wedges around the perimeter. Pinning right into the sidewalk entails driving pins into the pavements along the edges of the steel plates to stop motion. Recessing includes cutting out the location where the steel plate will be placed.

This results in the steel plate being flush with the sidewalk. In enhancement, when multiple steel plates are used and butt as much as each various other, they need to be bonded together at the longitudinal seams. Steel plates can be very unsafe, particularly when they are wet, unless they have an anti-skid finish applied.

Covering steel layers with a material that enhances rubbing helps motorcyclists and bicyclists maintain control, specifically in wet weather condition. Conditions which minimize sidewalk rubbing in job areas are of particular concern to motorcyclists and bicycles. An usual hazard in steel plate installations happens when the customer falls short to build properly tapered ramps from the street to the sides of the steel plate( s).

The Greatest Guide To Steel Road Plates

It presents a significant risk to motorcyclists and bicyclists that can easily blow up when they call the abrupt/steep tapered ramp and the steel plate. Properly tapered ramps permit users to safely cross over the steel plates. Tapers for steel plates are generally constructed of asphalt. The taper lengths differ from One state to another and generally range from 20 to read this article 1 to 120 to 1 (Steel road plates).

Guarantee appropriate overlap. Normally, steel plates should expand at least one foot past the pavement opening onto company ground.

The 8-Minute Rule for Steel Road Plates

Welding is browse around here made use of when more than one steel plate is utilized and they butt up to each various other. Plates must be countersunk when needed due to uneven streets.

His history includes the construction, inspection, learn more.

These durable steel plates play an essential function in improving construction safety and security, offering momentary streets, and making certain smooth procedures on numerous project sites. As a building and construction devices supplier, their relevance can not be overstated.

Report this page